Why "Forestry 4.0" Needs a Reality Check

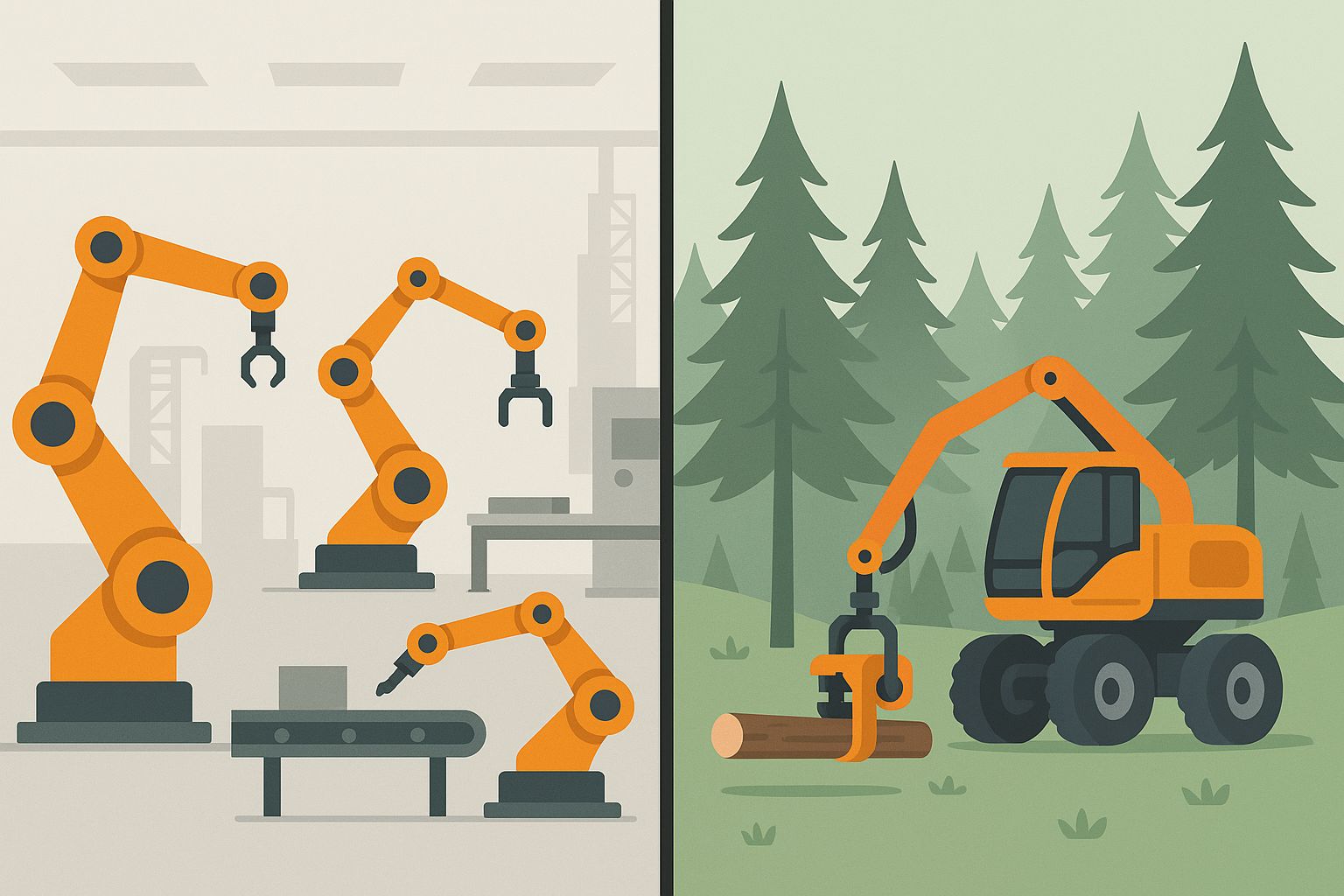

A recent paper claims "Forest 4.0 extends the Industry 4.0 paradigm to the forest sector." In reality, directly applying a manufacturing framework misrepresents how forestry technology truly evolved.

The Manufacturing Roots of "4.0"

The "4.0" concept originated in 2011 with Germany's "Industrie 4.0" initiative and was popularized by Klaus Schwab in his 2016 book, The Fourth Industrial Revolution. It outlines four sequential manufacturing revolutions:

Industry 1.0 (1760–1840): Steam power mechanizes textile mills

Industry 2.0 (1870–1914): Electricity enables assembly lines

Industry 3.0 (1950–1970): Computers automate factory processes

Industry 4.0 (2000–present): IoT and AI create connected smart factories

This neat progression works for factories—but forestry's path has been very different.

Forestry's Actual Productivity Leaps

The Chainsaw Revolution (c. 1920s–1960s)

Though Industry 1.0 transformed factories in the 1800s, foresters relied on axes and hand saws until motorized chainsaws became widespread in the 1950s–1960s. Studies suggest mechanization boosted productivity anywhere from 3× to 20× depending on task and forest type, with Silva Fennica research documenting significant gains in felling operations across different terrains and species.

The Cut-to-Length Revolution (c. 1970s–1990s)

In Nordic forests, the harvester + forwarder CTL system drove substantial productivity improvements. Research from the 1980s–1990s documented 10–15× gains in many operations and up to 70% time savings in thinning and clear-cut scenarios, though results varied by site conditions. McKinsey dubbed it a "giant leap" in mechanization—gains that dwarfed factory automation of the same era.

Digital Optimization Era (2000s–Present)

Since 2000, GPS, sensors, and telematics have delivered what studies report as modest double-digit efficiency gains—typically 15–40% improvements in fleet optimization and route planning. These are valuable optimizations built on a mechanized foundation, not revolutionary shifts.

Why the "4.0" Timeline Misleads

Industry 4.0 assumes uniform global progression. Yet forestry innovation followed different patterns:

Nordic countries led CTL adoption by the 1980s–1990s, while other regions followed later (Japan in the 2000s, for example).

Forestry innovations flowed from forest-rich regions—Nordic countries and parts of North America—rather than from manufacturing centers.

Academic & Terminology Confusion

Researchers have introduced multiple overlapping terms:

Smart Forestry (Komatsu's commercial brand)

Precision Forestry (academic focus on site-specific management)

Digital Forestry (generic digitalization umbrella)

Forest 4.0 (loosely applied Industry 4.0 concepts)

This terminology proliferation reflects ongoing efforts to frame forestry's digital transformation, but without clear consensus on definitions or scope.

Business Impact of Misapplied Frameworks

Relying too heavily on Forestry 4.0 thinking can create significant business risks:

Investment Misallocation

Chasing “4.0” buzzwords can divert capital from proven mechanization upgrades with far higher returns. For example, investing in IoT sensors before optimizing CTL operations risks missing 10× productivity gains.

Technology Sequencing Errors

The framework implies linear progress, while forestry often advances non-linearly. Some regions risk designing digital tools for processes that remain largely manual.

Vendor Confusion

Suppliers may bundle mechanization, digital, and analytics under the “Forestry 4.0” label, making it harder for buyers to evaluate specific capabilities and ROI.

Strategic Planning Gaps

Applying factory-style timelines underestimates forestry’s unique constraints: terrain variability, weather dependence, and skilled operator requirements.

Competitive Blind Spots

Companies fixated on “fourth revolution” tools may overlook competitors gaining market share by executing older, proven technologies more effectively.

Beyond Borrowed Revolutions

Instead of borrowed frameworks, forestry needs approaches that reflect continuous intelligence; ongoing learning and adaptation rather than discrete revolutions. This means:

Building systematically on mechanized foundations before adding digital layers

Integrating technologies based on operational needs, not chronological sequences

Adapting solutions to regional conditions and forest types

Measuring progress through productivity gains, not technology adoption rates

Conclusion

Forestry's technological story is richer and more complex than a simple "4.0" label suggests. Our industry's major advances; chainsaws, CTL systems, and now digital optimization don't align neatly with manufacturing chronologies. Rather than force-fitting borrowed frameworks, let's develop terminology that honors forestry's unique evolution and drives real value in the field.

The next time someone proposes a "Forestry 4.0" solution, ask: Does this build on our mechanized foundation? Does it address our specific operational challenges? Will it deliver measurable productivity gains? These questions matter more than fitting into someone else's industrial revolution.

Forestry doesn’t need factory slogans; it needs its own language for technology and progress.